It has been several years since we touched on the topic of Start-Stop Systems in any significant way. These systems have only gained in popularity in that time, as vehicle manufacturers try to squeeze as much efficiency from their systems as possible. While these systems generally remain the same, like all vehicle technology, they are always evolving as innovations are incorporated into them. This means that the vehicles you’ll service in 2026 will be different than those you serviced in 2023 when it comes to Start-Stop. So, we thought we’d gather some recent resources related to this service area in this month’s article.

Prime Time Start-Stop Primer

We’re going to start with a well presented and comprehensive Start-Stop article from Jeff Taylor on VehicleServicePros.com. In all candor, it is one of the best articles on this topic that we have ever seen. He starts by explaining why such an article is still needed in 2025: “The Start-Stop system isn’t new anymore, but it continues to confuse both drivers and technicians alike.” He then makes the case for gaining a better understanding of these systems at the shop and technician level in order to tackle these repairs more effectively and efficiently.

He first addresses the main system components of the Start-Stop system design and how they contribute to the solution as a whole. We especially like how he addresses the two main battery types used in these systems, EFB and AGM batteries. While it’s a fairly long excerpt, we think it is worth noting:

“EFBs are basically beefed-up versions of standard lead-acid batteries. They’re built to manage the added stress of Start-Stop operation. You’ll usually see EFBs in base model Start-Stop vehicles that don’t have a lot of extra electronics but still need to crank the engine more often than normal.

AGM (Absorbent Glass Mat) batteries are the next level up. These are designed for vehicles with heavier electrical loads or systems like regenerative braking. They recover charge faster, tolerate deeper discharges, and hold up better under heat and vibration. Since they’re sealed, there’s no worry about leaks, which is why they can be mounted in less traditional locations like under the rear seat or in the trunk.”

He notes that some manufacturers use a 2-battery design (primary starting battery plus auxiliary battery to handle accessory loads during stops) while most use a 1-battery design. He covers the other system components with the same level of detail. As he addresses the various system components, he also identifies common DTCs related to each, choosing different manufacturers for his examples to provide a wide range of make and model coverage.

He then delves into Start-Stop diagnosis, warning not to skip the basics. Is battery condition good? Is it properly in synch with the vehicle? He uses the example of a 2019 F-150 with a recently replaced battery and a bunch of problems. It was determined that the battery was never reset, which once done, solved the problem. He also provides a manual reset procedure: “To reset the BMS, turn the key to the “on” position without starting the engine (or press the start button without your foot on the brake). Flash the high beams five times, then press the brake pedal three times. If the battery light starts flashing, the reset is working. Once it stops, cycle the ignition off and back on to confirm.”

There’s no way we could quickly recap this entire article. The best bet is to check it out for yourself. We have no doubt that it’ll earn a bookmark in your browser and that you will reference it often in the future.

Start-Stop – What Gets Changed to Make These Systems Work

Now we shift to a quick-hit article that runs down 10 ways that these systems differ from traditional ICE system designs. In this recent Euro Intel email piece, Andrew Markel from Babcox breaks down the various components that have been modified or upgraded to enable Start-stop systems to work effectively.

As you can imagine, there is a great deal of emphasis on the battery, starter and electrical system, as he addresses how these aspects of the system have been adapted to support the exponentially greater number of starts that these systems experience. He also makes a great point about the ways these systems are controlled, highlighting how they incorporate a greater number of sensors and required more detailed control:

“A stop/start system is not just one module. It is a complex strategy among many modules sharing information from cabin humidity to crankshaft position to determine what happens at the next stoplight. For the technician, it means that serial data communication bus and electrical diagnostics will be much more important in the future.”

This is a great one for understanding the key components of these systems as well as how they work together to deliver the promised functionality.

Diagnosing Start-Stop Systems

Next, we turn our attention to diagnosing Start-Stop equipped vehicles. In this article on tomorrowstechnician.com, they address the major systems that enable Start-Stop functionality and highlight areas of focus, providing diagnostic tips along the way.

They break the system down into four keys areas: the battery, the starter, the HVAC system, and overall system control. With regard to the battery, they emphasize the fact that the electrical system is constantly monitoring battery condition (via numerous inputs) to know whether it is OK to shut the engine down when the vehicle next comes to a stop. They make a great point about testing the battery or batteries in a Start-Stop System:

“Don’t just use a voltmeter to determine the state of charge: voltage readings can be different for AGM batteries. Due to differences in internal construction, AGM batteries have lower internal resistance when compared to a conventional lead-acid battery. AGM can charge faster and recover faster after starting the engine. Also, AGM batteries perform better at colder temperatures… More sophisticated battery testers can take these internal engineering features into account.”

This article provides a great complement to the two earlier articles. It builds on the subject of power management and how these vehicles have migrated to CAN-Bus network control over time for improved communication. One topic that we have always focused on throughout our blog articles is the interconnectedness of vehicle systems and this article provides a great picture of how the Start-Stop System is situated within the overall system architecture.

Start-Stop Systems and Hybrids

We’ll wrap with another short article that addresses the consequences of Start-Stop functionality on hybrid vehicle performance and longevity. In this article on import-car.com, the writers talk about the ways that hybrids are impacted differently by the repeated stops caused by Start-Stop Systems.

“Hybrid vehicles deliver a brilliant mix of electric efficiency and gas-powered range. But beneath that seamless driving experience is a gas engine working in ways it was never designed for… constant stops and starts. Those frequent restarts bring unique demands that can lead to premature hybrid engine wear and sludge buildup, often leaving owners confused when issues appear.”

They go on to explain how Start-Stop is different for hybrids, since, the gasoline engine runs only when needed. They identify the issues that can arise as a result of this limited run time and the maintenance steps that should be taken to minimize the negative impact. It’s a great article that addresses two growing trends within the North American carparc: hybrids and Start-Stop Systems.

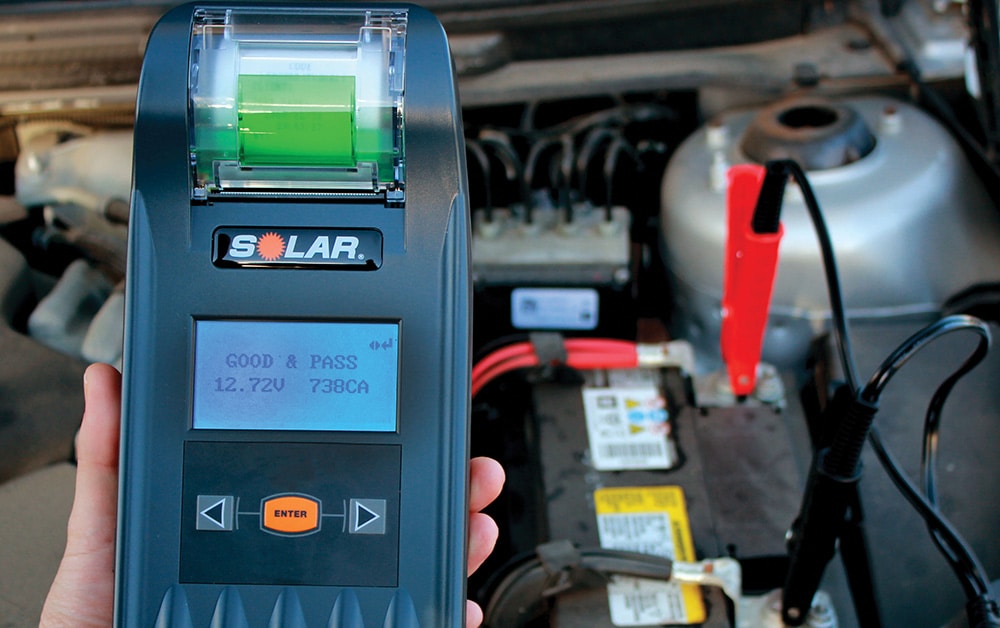

BA327: A Steady Companion for Reliable Start-Stop Analysis

As we can see from the articles above, there’s a lot more to Start-Stop Systems than just the battery. That said, the battery is the starting point for repair diagnosis as well as preventive maintenance steps. As noted above, it is critical with the AGM and EFB batteries used in these systems that you deploy a quality testing solution to avoid a misdiagnosis.

Our Model BA327 is the perfect shop battery testing solution for Start-Stop vehicles. It has specific testing routines for AGM Flat Plate (traditional shape), AGM Spiral Wound, Start-Stop AGM and Start-Stop EFB batteries, enabling you to dial in your testing process exactly to the vehicle’s battery type. It accurately tests battery capacities to 2000 CCA, can test against a variety of testing criteria (CCA, CA, DIN, etc.) and can even test discharged batteries. Add in multiple languages, 10 ft. cable leads, field-replaceable cable ends and a handy storage case and it all adds up to a unit that addresses the exact needs of busy shops.

How about you? Have Start-Stop Systems created any issues for your service routine? Have you developed any best practices to make interacting with them easier, quicker or more effective? We’d love to hear about it in the comments below, as would your fellow readers.