Editor’s Note: It has been several years since we first published this article, one of the most popular articles in the history of our blog. In that time, we’ve welcomed thousands of new subscribers to our newsletter and it makes sense to come back to this one. That said, we have updated it for our long standing subscribers, in the hopes that they can gain new insight into this important area of vehicle maintenance.

There are dozens, maybe even hundreds, of options when looking for a battery maintainer for your car, truck, boat, ATV or other vehicle. It can be confusing to choose among all those options, especially when there are many different approaches to this seemingly simple task. For many reasons, we’d say that PRO-LOGIX battery charger/maintainer products deliver the most beneficial maintenance routines on the market today. In this month’s article, we are going to lay out the reasons why we feel this way.

The entire point of battery maintenance is to keep your batteries in good shape while they are not being used, so they are ready when you next want to drop the boat in the water or take old Betsy out for a cruise. In addition, the bigger goal is to get longer life from your batteries so you maximize your investment and save money in the long run. Every aspect of the PRO-LOGIX approach to battery maintenance is designed to improve battery health, increase reserve capacity and enable vehicle owners to get the greatest return on their battery investment.

We could probably provide two dozen aspects of the PRO-LOGIX approach that support the above goals, but we are going to focus on six specific aspects that we think are the most important:

- Optimized Charge Routines for Different Battery Types

- Automatic Operation that Responds to Each Battery’s Needs

- Exercise is the Key to Health – Trickle Charging is a Dirty Word

- Temperature Compensation

- Effective Charging of Totally Dead Batteries

- The Ability to Overcome Power Outages

Optimized Charge Routines for Different Battery Types

This is critical when it comes to a battery maintenance option, since, by definition, a battery maintainer is going to see its most frequent use in long-term charging situations. That means that your battery(ies) are going to be significantly exposed to the maintainer and its charging profile. This makes the maintenance charging profile far more critical than that of a standard charger, which might be used once or twice a year on a given vehicle and for just a few hours at a time, rather than for days or weeks at a time.

PRO-LOGIX battery maintainers have distinct settings for each battery type serviced and are capable of servicing a wide variety of battery types, including Flooded, AGM, Spiral Wound, Gel Cell, Marine, Deep Cycle and LiFePO4 Lithium batteries (battery types serviced vary by model). This is really important no matter what type of batteries you have, but is especially important if your vehicles utilize batteries other than standard flooded batteries. For instance, if you have several AGM batteries, you need a maintenance option with an AGM-specific charging routine. AGM batteries have specific requirements when it comes to the charge profile and are very sensitive to overvoltage, which can cause deterioration of battery health.

Many maintainers don’t require you to select a battery type. While convenient, the problem with a maintainer that is designed this way is that it usually uses a generic, “safe” routine that won’t harm any lead acid battery type, but is not optimized for any one battery type. This means that it isn’t dialing in its routine and is often short charging batteries in order to avoid overcharging them. Over time, exposure to a non-specific charging routine can degrade, rather than improve, your battery’s health and longevity. For instance, you are likely undercharging flooded batteries with such a charger, which can lead to sulfation build-up, which saps a battery’s health and reduces its longevity.

Automatic Operation that Responds to Each Battery’s Needs

PRO-LOGIX battery maintainers deploy an advanced, automatic charging routine that responds to the specific needs of each battery charged, allowing them to deliver an optimized service every time. Effectively, this means that the charger is going to adjust its operation based on the way the battery under charge is receiving the energy delivered by the maintainer. If the battery shows signs of sulfation, PRO-LOGIX charger/maintainers will automatically shift to battery repair mode and then resume normal charging when the battery accepts energy in a more normal way. Similarly, if a battery is heavily discharged at the start of the charging cycle, PRO-LOGIX will automatically shift to a soft start mode to safely and beneficially bring the battery’s voltage to a more normal range and then resume standard charging. In the end, the goal is to deliver energy to the battery in the most beneficial way, regardless of size, type, condition or state of charge, and PRO-LOGIX leads the way in this regard.

Temperature Compensation

In our introduction to this article, we stated that every aspect of the PRO-LOGIX approach to battery maintenance is designed to improve battery health, increase reserve capacity and enable vehicle owners to get more from their battery investment. Temperature compensation is a great example of us walking our talk. It costs more and makes the product more complex, but you really can’t give a battery what it truly wants if you aren’t temperature compensated. Put simply, a colder battery wants more energy and a hotter battery wants less energy. The world isn’t a constant 70˚F and neither are your batteries. To get the most out of your battery maintenance efforts, you need a battery maintainer that adjusts its charging routine based on battery temperature.

Exercise is the Key to Health – Trickle Charging is a Dirty Word

Let’s start with the second part of the above statement. Trickle charging (float charging) is how it was done for decades: bring the battery to full charge and then hold the voltage (usually around 13.2V). We believe that this approach is flawed on several levels. First, we think it doesn’t do much for battery health over time and, second, we think that it has a tendency to contribute to dried out batteries in extended maintenance situations. There’s a better way.

The PRO-LOGIX enhanced maintenance process has two key stages that are both unique to us and very beneficial for batteries under extended service. The first unique aspect of the PRO-LOGIX approach is that, upon reaching a full, complete charge, we put the battery into a rest phase. We don’t want the battery to be constantly under service. It isn’t necessary and it isn’t beneficial. Instead, we more closely mimic the way a battery is used when the vehicle is in service, with periods of activity and periods of rest. A known good battery will not self-discharge in just a few days, otherwise we’d see hundreds of jump starters in use every time we entered an airport parking lot. This rest phase is what makes PRO-LOGIX far less likely to contribute to drying out batteries in extended charging and contributes to longer battery life. The second unique aspect of the PRO-LOGIX approach is that, when the maintainer exits the rest phase, it enters an exercising phase. The exercise phase puts a load on the battery, simulating a starting event, which allows us to get a full, deep charge into the battery in the next charging cycle, which occurs immediately upon completion of the exercising phase. We believe that this rest-exercise-full charge cycle is far more beneficial for all battery types than a basic trickle charge.

Effective Charging of Totally Dead Batteries

Just as you need a charger that can handle different battery types, different battery conditions and different temperatures, you need a charger/maintainer that can manage the occasional totally dead battery. It sounds pretty basic, but many smart chargers and maintainers can only manage 12 Volt batteries with a state of charge above a certain threshold voltage, be it 1V, 3V, 5V, etc. The higher the threshold, the more likely you are to run into a situation where your charger cannot engage your battery. That’s a problem, one which we call The Dead Battery Dilemma, as in, “I bought a charger to charge my dead battery, but my battery is so dead that my charger doesn’t work!” But, that’s never a problem with PRO-LOGIX. All PRO-LOGIX chargers and maintainers incorporate a Forced Start routine where, assuming the only issue is that the battery is stone cold dead, after checking that all of your connections are correct, you can hold down the START/CHARGE button for 3 seconds and force the maintainer to engage the battery. This saves lots of time and hassle.

Ability to Overcome Power Outages

Several PRO-LOGIX battery maintainer models (PL2112, PL2140, PL4020, PL4050) incorporate our Recovery Mode (RM) technology to enable the charger to overcome power outages. On models so equipped and set to RM on (if adjustable), the maintainer will remember its last programmed settings when power is interrupted and restart charging under those settings when power is restored. This is a really big deal if your baby is charging in the third bay on a cold February day and you are down south living the snowbird lifestyle. With PRO-LOGIX, you can rest assured that, when power resumes, your battery is getting when it needs, without human intervention.

PRO-LOGIX – the Complete Package

Compare these six aspects of PRO-LOGIX battery maintenance against the competition and you will see that not all charger/maintainers are created equal. PRO-LOGIX is not only easier to use than most other options and better for the long-term health of your battery(ies), it will also help you save money by extending the useful life of your batteries and ensure your vehicles and toys are ready for action when you are.

We have many models that serve diverse application needs, but here are three of our most popular PRO-LOGIX Battery Maintainer Models:

PL2112

12V 1.0A

Battery Charger/Maintainer

Perfect for servicing the smaller batteries found in many powersports application, it brings the versatility to properly charge Flooded, AGM, Spiral Wound and Deep Cycle Lead Acid batteries, plus LiFePO4 Lithium batteries. Features three output options and includes Recovery Mode to overcome power outages.

PL2140

6/12V 4.0A

Battery Charger/Maintainer

Almost an identical feature set as the PL2112, the PL2140 adds the ability to service 6V batteries and increases the power output to 4 Amps, increasing its effective range from small batteries all the way up to car/SUV/truck batteries. This unit is our all-around champ.

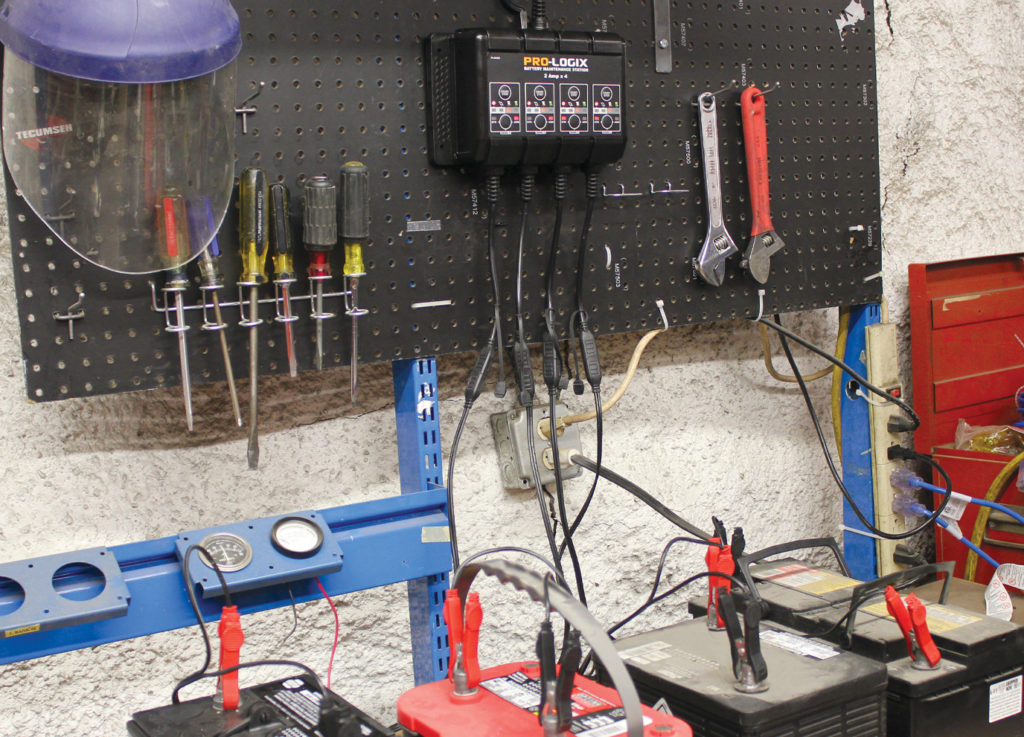

PL4050

6/12V 4 x 5.0A

Battery Maintenance Station

If you find yourself managing lots of batteries from all of your equipment, the PL4050 is for you. This unit can service up to 4 batteries (Flooded, AGM, Spiral Wound or Deep Cycle) simultaneously. It has three 12V channels and one 6/12V channel, with each channel completely independent from the others, so a problem battery on one channel won’t impact charging on the other channels.

This time of year is the busy season for active battery management, as now is the time that vintage cars come out for Cars and Coffee, ATVs and Side-by-Sides hit the dusty trail and personal watercraft are in high rotation at the cottage. Maintaining the batteries in this equipment, as well as the batteries in your daily driver(s) helps to ensure that they’re ready when you’re ready to use them. For instance, between weekends, throw your jet ski battery or trolling motor battery onto a PL2140 for a good, long maintenance cycle so it is in top shape when you next want to turn the key. PRO-LOGIX makes long term battery management easy and effective.

5 Responses

I “opportunity” charge two AGM 24F vehicle batteries year-round, leveraging temperature-compensating Pro Logic 2320s modified with quick disconnects whenever I park the vehicles in my unheated garage in Montana. The battery life for each has far exceeded my expectations. Where temperature extremes are prevalent. I have recommended this approach to many others.

Bill – Thanksa for your note. We are very glad to hear that your PRO-LOGIX charging strategy continues to perform well for you and that you continue to get longer than expected battery life. We use your example often when we speak to customers at trade shows. Wishing you all the best. Thanks again, Jim

Help I lost charger cord how much to replace

Unit??

Rodger – Thanks for your question. We have many different units, so it’s hard to say which charger you need. Please call our Tech Line at 800 three two eight 2921, option #2. They’ll be able to identify the correct charger. Thanks, Jim from Clore Automotive

The most intelligent Battery chargers in the market Pro Logix check out the Nightmare on Elm Street Project Vehicle 2024 Can Am Maverick R XRS using the PL2320