Whether in trade publications, on iATN or other forums or at trade shows, it seems there are few challenges as vexing as intermittent faults. They present difficult diagnostic situations, often become a major time suck, result in a higher incidence of comebacks and can lead to customer dissatisfaction if not handled properly. In this article, we have pulled together several resources that we hope will help you as you tackle intermittent faults in your service bays.

Chasing Intermittents is Like Chasing Ghosts

We’ll start with an oldie but a goodie. In this article from Import Car, Larry Carley provides a great overview of the unique challenges caused by intermittent electrical problems. He invokes one of the most common mantras we have seen since we started writing these articles, which is that it is important to approach diagnostic dilemmas, especially intermittent electrical problems, with a clear plan, “The best approach to dealing with intermittent electrical faults is a logical approach that will help you find and fix the fault now.” He goes on to identify the tools and techniques that technicians can use to resolve intermittent electrical issues.

Back to the mantra invoked in Larry Carley’s article referenced above – have a plan.

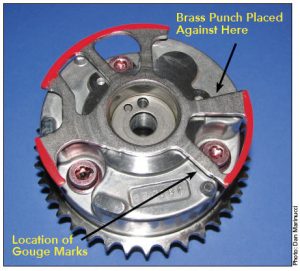

Electrical/Communication Error Red Flags Mechanical Failure

A Critical Tool for Identifying Intermittent Fault Root Causes

From an equipment perspective, the common thread running through the above referenced resources is the Digital Storage Oscilloscope (DSO, or scope). In this article from SearchAutoParts.com, Bernie Thompson focuses on various circuit designs, noting where the scope would be connected to each particular circuit and what the expected output would be. For those less accustomed to deploying a scope for diagnostic purposes, he recommends using one daily, as repetition will allow improved mastery over its use and deployment, yielding significant benefits. As he states, “Once you start to see what the picture on your scope is telling you, you will be able to speak the language of electronics. This language will teach you many things and soon you will wonder how you ever repaired a vehicle without knowing this hidden language.”

Intermittent faults are a tricky business that can lead you down blind alleys and into diagnostic quagmires. The common theme from all of the authors of the above resources is the need for a diagnostic plan of attack and the usefulness of a logical approach. With such a framework in place, pinpointing the root cause of an intermittent fault can be done in a more effective and time efficient manner.