Charging Low Voltage (12/24V) Lithium Batteries – An Update

Several years ago, we first explored the increasing prevalence of lithium batteries being deployed in low voltage (12V/24V) vehicle applications. These include usage of lithium batteries as the starting battery in an internal combustion engine (ICE) vehicle, as well as the low voltage battery in Hybrid (HEV), Plug-in Hybrid (PHEV) and Battery Electric Vehicle (BEV) vehicle designs. In this month’s article, we further explore this topic, as lithium batteries continue to gain exposure in vehicle applications, creating more questions for our customers related to how to manage these batteries.

Like many things in life, this is a bit of a good news / bad news situation for service shops and the many outlets serving their needs. The bad news portion of the story is that battery types continue to proliferate in the North American carparc. As we have counseled previously, these battery types have different needs when it comes to servicing them. When I came to Clore back in 2002, we really only dealt with standard and deep cycle flooded acid batteries. Now, there’s an alphabet soup of battery types that today’s technician could encounter. This adds complexity for service operations that have to diagnose and repair modern vehicles.

The good news is that, with the switch to smart battery charging products in the last twenty years, today’s battery chargers typically incorporate sophisticated chips and charging routines in their design that allow them to manage many different battery types (more on that below). This helps to minimize the equipment investment required to keep up, which is a welcome development for shops

Lithium Batteries in Low Voltage Applications

We have heard for years about the use of lithium batteries in high voltage (BEV, PHEV and HEV) battery packs. But, lithium batteries are also sneaking into a wide variety of low voltage vehicle applications. The reality is that lithium batteries are found in considerably more makes and models than was the case just five years ago, to the extent that the LiFePO4 (LFP) lithium battery really needs to be added to the growing list of commonly encountered low voltage application vehicle batteries: Flooded, AGM, Spiral Wound, Start-Stop AGM, Deep Cycle/Marine and EFB lead acid types, plus LiFePO4 lithium type.

Our textbook example of the use of a lithium starting battery in an ICE vehicle design is found in M-Series BMW models, where the starting battery was switched to the LiFePO4 lithium battery type as early as 2016. Since then, many highline (luxury, performance, exotic) vehicles have made the switch to LiFePO4 starting batteries. Our textbook example of non-ICE vehicle low voltage lithium battery deployment is found in Tesla Models S and X, which switched to lithium batteries for the low voltage battery (from AGM) in mid-year 2021. Vehicle manufacturers are making this switch for a variety of reasons, including LiFePO4 battery performance, LiFePO4 battery cycling ability, increased vehicle power demands, longer LiFePO4battery lifespan and the relative safety of LiFePO4 vs other lithium battery types.

Which Lithium Battery?

For service shops, it is really important to know that there are many different lithium battery types, each with different chemistries, cell counts and charging requirements. It is very important to understand the specific lithium battery deployed in a vehicle under service. The good news here is that our considerable research on this front continues to confirm that there is really only one lithium battery type installed as an OE-specified lithium battery in low voltage (12V/24V) vehicle applications in North America and that is the lithium iron phosphate (LiFePO4, LFP) battery.

That said, it is important to know that other lithium battery types exist and that each lithium battery chemistry has its own charging requirements. Like AGM and Spiral Wound batteries, but even more dramatically, lithium batteries are very sensitive to excessive voltage (over-voltage) conditions. In some cases, over-voltage conditions can lead to dangerous situations. So, it is important to ensure the equipment used to service them is properly matched to the lithium battery type under service. The voltage requirements of different lithium battery chemistries varies by type, which is why it critical to match any charger used to the specific lithium battery type being serviced. All PRO-LOGIX battery chargers that feature lithium capability are specifically calibrated to service LiFePO4 lithium batteries.

Managing Lithium Vehicle Batteries in the Real World

Well, we just laid a lot on you. Battery type proliferation… lithium battery sensitivity to over-voltage conditions… safety considerations. Yikes! What are the implications for today’s shops, who encounter these batteries and have to service them and the vehicles they are installed in on behalf of their customers? Back to one piece of good news above: (to our knowledge) there is only one lithium battery type installed as an OE-specified lithium battery in low voltage (12V/24V) vehicle applications in North America. And, the vast majority of lithium batteries sold in the aftermarket for vehicle low voltageapplications are also the same lithium battery type, the LiFePO4 lithium battery.

PRO-LOGIX Has You Covered When Servicing LiFePO4 Lithium Batteries

When it comes to servicing LiFePO4 lithium batteries, our PRO-LOGIX line of intelligent battery chargers has you covered, whether you are running a dealership service operation, an aftermarket repair shop or are trying to keep your vehicles in top condition in your home garage. The precise charging control and advanced charging logic that is built into every PRO-LOGIX model is exactly what is needed to deliver beneficial service to these batteries.

Charging precision is a key feature of the PRO-LOGIX charging process. Today’s smart chargers, if they are doing what they should, deliver some variation of a multi-phase charging process to all battery types, including LiFePO4 lithium batteries. That’s where there’s commonality among most products out there. As always, though, the devil is in the details. And the details are where PRO-LOGIX shines.

Temperature Compensation

PRO-LOGIX battery chargers control for a wide variety of variables to ensure that each battery serviced is getting exactly what it wants and needs for a beneficial charge. We have emphasized this before, but it is even more critical when servicing lithium batteries. For instance, our temperature compensation feature adjusts charge parameters based on charging temperature, which can have a drastic impact on how a battery accepts a charge. In addition, we have a low temperature cut-off built into our lithium charging routine, as most LiFePO4 lithium batteries cannot be safely charged below 32˚F (0˚C).

Soft Start Mode

Another great example comes when charging a heavily depleted LiFePO4 lithium battery. When a PRO-LOGIX charger encounters such a situation, it automatically engages a soft start mode to slowly and safely bring that battery back to a normal state of charge (SoC). Failing to manage the battery in this manner could negatively impact its longevity at best and could result in an unsafe situation at worst.

Delivering Power Exactly the Way the Battery Wants It

Even more importantly, we deliver power to the battery in a very precise fashion, with a constant current bulk charge phase and constant voltage absorption phase. Many competing products will say, “So what? So do we.” While that may be true in theory, what we see in many competing products is far from ideal in practice, with limited control of the charging parameters and even strange power delivery routines that are in opposition to best practice.

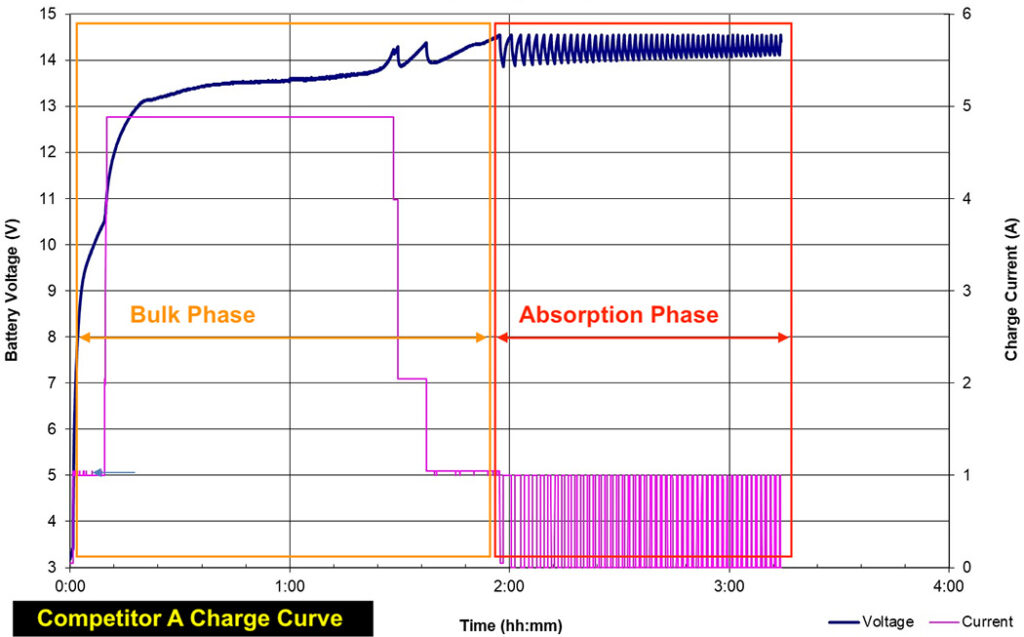

Here’s an example of a popular charging brand’s lithium charging approach:

We’ve highlighted the two sections of the charge curve, bulk charge phase and absorption phase. Following best practice, the bulk charge phase of this charge routine should reflect constant current behavior. In other words, the charger controls the current at a set rate and allows the voltage to rise to a trip point that would move you out of this phase. Here, what we see is current ramping up to the “constant current” portion of the bulk phase and then ramping down until the battery’s voltage reaches the trip point.

Again, following best practice, the absorption charge phase of this routine should reflect constant voltage, allowing the current fed to the battery to slowly drop down as the battery advances to a completely full charge. Here, what we see is voltage oscillating by as much as 0.5V as current ramps up and down. While this charge routine may not be catastrophic to the battery in the short term, servicing a LiFePO4 lithium battery in this manner could be detrimental to long term battery health.

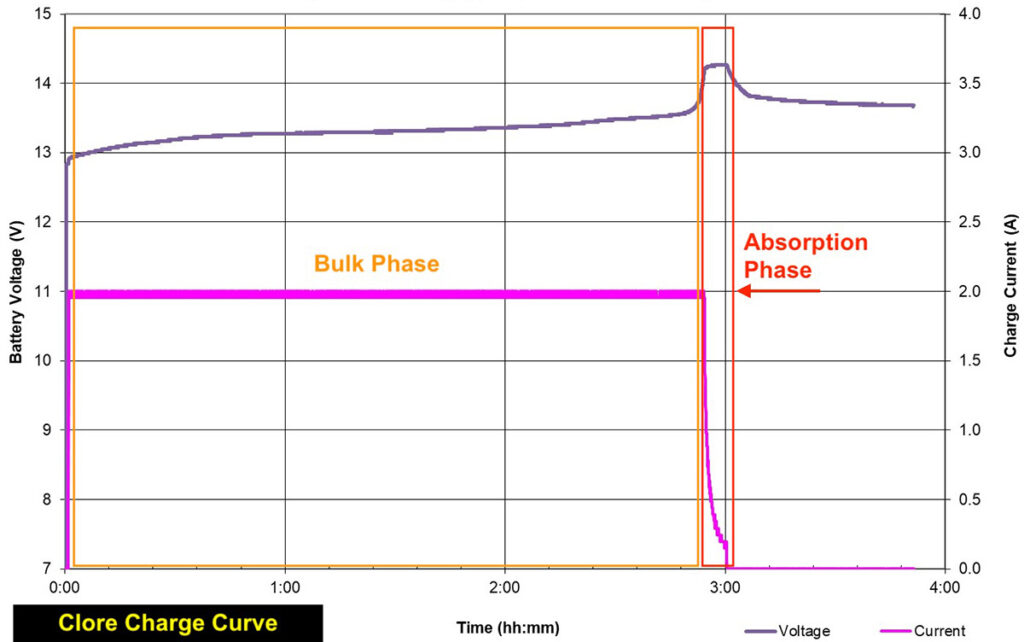

Contrast this with the PRO-LOGIX approach to charging using the same battery and charge rate:

With PRO-LOGIX, we see a true constant current bulk charge phase, holding output current steady as voltage rises, exactly as prescribed by battery manufacturers and generally accepted best practices for charging advanced batteries such as LiFePO4 batteries. Then, we see a true constant voltage absorption charge phase, holding output voltage steady with current acceptance tapering down as the battery reaches full charge, exactly as prescribed by battery manufacturers and generally accepted best charging practices.

This level of detail might elicit a yawn, and we get it. Do you really need to know how the ions move from plate to plate within a battery? Of course not. But, it is important to know which charging equipment is capable of delivering the precise battery charging routines required to beneficially service modern batteries such as AGM, Spiral Wound and LiFEPO4 batteries. LiFePO4 batteries are very expensive, often costing 2-4 times more than an equivalently powered lead acid battery. The last thing that you want to do is expose your (or your customers’) lithium batteries to uncontrolled and potentially damaging charge routines. Whether you’re servicing the lithium battery in a customer’s BMW, Mercedes, Porsche, Audi, Tesla or other make, it makes sense to choose the charging equipment that’s going to serve them best.

That’s why we believe we are delivering best-in-class lithium battery service. When you look at charging precision and beneficial outcomes, it’s hard to beat PRO-LOGIX. When you add in our power supply mode (some models) and other great convenience features, PRO-LOGIX battery chargers deliver a great charge every time and make life easier for today’s busy professional technicians.

Here’s a quick look at the PRO-LOGIX Lithium-Capable Charging Lineup:

We have a full menu of lithium-capable charging options, from our super-powerful PL6850 (120A) to our relatively modest PL2112 (1.0A). Rest assured that, no matter what size LiFePO4 lithium battery you need to service, there’s a PRO-LOGIX model to meet your needs.

Model No. PL6850

12/24V 120A Flashing Power Supply

and HD Battery Charger

Our flagship model, in Power Supply Mode, the PL6850 provides the power to keep up with even the most demanding Euro module reprogramming tasks. In Battery Charge Mode, with unlimited 120A 12V output, it makes quick work of the largest 4-battery and 8-battery packs found in Class 8 trucks and offroad equipment.

Model No. PL6100

(recently updated for LiFePO4) 12V 100A Flashing Power Supply and 60/40/10A Battery Charger

Our standard shop service model for passenger vehicle service and non-German vehicle module reprogramming support, the PL6100 features the ability to maintain vehicle system voltage from 13.1-14.9V (adjustable in 0.1V increments) to support a wide variety of reprogramming and ADAS recalibration tasks, as well as providing beneficial battery charging service to many different battery types.

Model No. PL2320

6/12V 20A Battery Charger /

Maintainer / Power Supply

The PL2320 is the perfect battery charger for service bay deployment. Charges a wide variety of battery types quickly and efficiently. Plus, its 20A Power Supply Mode provides excellent support for diagnostic, repair and maintenance routines. As we like to say, “When the hood goes up, the PL2320 should go on!”

Model No. PL2310

6/12V 10A Battery Charger /

Maintainer / Power Supply

The baby brother to the PL2320 above, the PL2310 services Flooded, AGM, Spiral Wound, Deep Cycle and Marine lead acid batteries, plus LiFePO4 Lithium batteries. Like all PRO-LOGIX chargers, it features a “Forced Start Mode” that enables it to engage even totally dead (0.0V) batteries, allowing you to avoid the Dead Battery Dilemma.

Model No. PL2410

12/24V 10A Battery Charger /

Maintainer / Power Supply

The weird “Cousin It” to the PL2310 above, the PL2410 provides the same service as the PL2310, but in 12/24 mode rather than 6/12V mode. It does meet a specific needs, though, as there are only a limited number of full powered 24V chargers available in the market.

Model No. PL2140

6/12V 4.0A Battery Charger /

Maintainer / Power Supply

The PL2140 is the perfect all-around charger for a home garage. It features advanced PRO-LOGIX charge routines, an enhanced maintenance mode for optimal long-term storage charging and multiple output options, including clamps, rings and a 12V male outlet. It also can overcome power outages without needing to be reset.

Model No. PL2112

12V 1.0A Battery Charger /

Maintainer / Power Supply

The PL2112 is the little brother to the PL2140, with the primary difference being its charge rate (1A vs 4A). Its 1A charge rate makes it ideal for servicing smaller (<30Ah) batteries, including the smaller lithium batteries found in powersports applications. Like the PL2140, its enhanced maintenance mode makes it the perfect for charging seasonal use vehicle batteries during the offseason.

How about you? If you are running or working in a shop, are you encountering more lithium batteries these days? What about our personal users / garage mechanics? Are you starting to see lithium batteries installed in your newer vehicles? Or, have replaced a lead acid battery with a lithium battery in your ATV, side-by-side, wave runner or other toy? How are you servicing these batteries today? Do you have any questions? We’d love to hear about it in the comments below, as would your fellow readers.

4 Responses

I am interested in Litium batteries in my golf cart (currently 36v). What are your suggestions and comments about Litium in these applications?

Larry – Thanks for your question. Lithium batteries can make a lot of sense for golf cart applications. They should provide longer life and improved cycling capability (ability to be discharged deeper and still recover to normal reserve capacity). That said, they’re likely to cost quite a bit more. So, it comes down, typically, to what you’re willing to spend. We would always caution you to focus on safety and make sure any batteries purchased for this application have a good, protective battery management system (BMS) built into them. Thanks, Jim from Clore Automotive

Do the jump start the same a s a lead acid battery?

Rick – Thanks for your question. Yes, low voltage lithium starting batteries in ICE vehicles jump start the same as a lead acid battery. So, you can use traditional JNC and Booster PAC units to jump start these as well as our newer lithium jump starters. The same is true when “jump starting” the low voltage battery found in EVs and Hybrids. Any jump starter (lead acid or lithium) can be used to augment the low voltage battery to get these vehicles started. Thanks, Jim from Clore Automotive